Industrial inspection and imaging technologies have evolved rapidly, helping industries enhance safety standards, product quality, and overall operational efficiency. Central to these systems are X ray high voltage generators, which provide the precisely controlled electrical power needed to generate X-rays with stable energy and consistent output. Their reliability is critical in applications where accuracy, repeatability, and long-term performance are essential.

A robust high-voltage generator solution ensures X-ray systems function effectively across diverse industrial environments. From manufacturing and electronics to food safety and security screening, X-ray technology enables informed decision-making while preserving the integrity of inspected products. The following sections outline the ten most important industrial applications where X-ray high voltage generators play a crucial role.

1. Non-Destructive Testing for Structural Integrity

Non-destructive testing is one of the most established applications of X ray high voltage generators. Industries such as aerospace, oil and gas, shipbuilding, and automotive manufacturing rely on X-ray inspection to examine welds, castings, and structural components. Internal defects like cracks, voids, and inclusions can be detected without altering the material.

A stable high-voltage generator solution allows inspectors to adjust penetration depth and image contrast, ensuring accurate assessment of internal structures. This helps prevent failures, improve safety, and extend the lifespan of critical components.

2. Security Screening and Cargo Inspection

Security screening systems depend heavily on X-ray high-voltage generators to inspect luggage, parcels, and cargo containers. These systems are widely used at airports, seaports, logistics hubs, and border checkpoints to detect concealed weapons, explosives, and contraband.

Consistent voltage output is essential for generating clear images that differentiate materials based on density. A reliable high voltage generator solution enables uninterrupted operation in high-traffic environments, supporting public safety and efficient cargo flow.

3. Food and Beverage Quality Inspection

Food manufacturers use X-ray high-voltage generators to maintain product safety and compliance with strict quality standards. X-ray inspection systems detect contaminants such as metal fragments, glass, stones, or bone pieces inside packaged food products. They also verify fill levels, portion sizes, and package integrity.

By using a precise high-voltage generator solution, food processors can identify issues early, reduce waste, and ensure consistent product quality while maintaining high production speeds.

4. Material Composition and Analytical Testing

Material analysis applications, such as X-ray fluorescence and X-ray diffraction, rely on accurate energy control provided by X ray high voltage generators. These techniques help determine elemental composition, coating thickness, and crystalline structure of materials.

Industries including mining, metallurgy, electronics, and research laboratories use these methods for quality control and development. A consistent high-voltage generator solution ensures repeatable measurements and reliable analytical results across different samples.

5. Automated Component and Part Sorting

Modern production lines use X-ray-based sorting systems to inspect and classify components based on internal characteristics. X-ray high voltage generators power systems that detect internal defects, verify fill levels, and confirm correct assembly inside sealed components.

This application is common in electronics manufacturing, automotive parts production, and packaging operations. A dependable high voltage generator solution supports rapid inspection and accurate sorting without slowing production.

6. Printed Circuit Board Inspection

Printed circuit boards are becoming increasingly complex, with multilayer designs and miniature components. X-ray high voltage generators enable inspection systems to examine solder joints, internal traces, and component alignment that are not visible from the surface.

Electronics manufacturers rely on a stable high-voltage generator solution to detect defects early in the production process, reducing rework and improving overall product reliability.

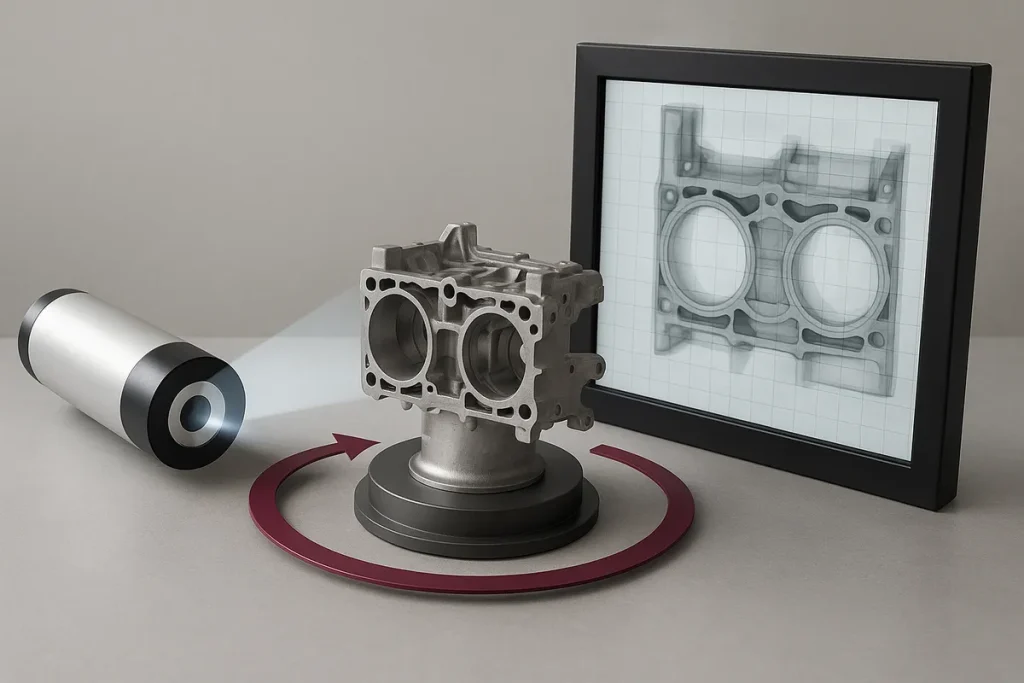

7. Industrial Computed Tomography Imaging

Industrial computed tomography uses X-rays to create three-dimensional images of internal structures. This application relies on powerful X ray high voltage generators to penetrate dense materials and capture high-resolution data from multiple angles.

Industrial CT is widely used for failure analysis, design validation, and reverse engineering in aerospace, automotive, and advanced manufacturing sectors. A consistent high voltage generator solution is essential for accurate reconstruction and repeatable imaging results.

8. Sterilization of Medical and Industrial Products

X-ray-based sterilization systems are used to eliminate microorganisms from medical devices, pharmaceuticals, and selected food products. X-ray high voltage generators control the radiation dose required to achieve effective sterilization without damaging sensitive materials.

Compared to chemical sterilization methods, X-ray sterilization offers a clean and residue-free process. A precise high-voltage generator solution supports compliance with safety and regulatory standards.

9. Thickness Measurement and Level Detection

Manufacturers use X-ray systems powered by X ray high voltage generators to measure material thickness and detect product levels in containers. This is especially useful in industries such as plastics, metals, chemicals, and packaging.

Real-time thickness gauging helps maintain uniform product dimensions and reduce material waste. A stable high-voltage generator solution ensures accurate measurements even in high-speed production environments.

10. Quality Control and Process Optimization

Quality control systems across manufacturing sectors depend on X-ray high voltage generators for both static inspection and continuous monitoring. Radioscopy systems inspect products as they move along production lines, identifying defects before final packaging.

A reliable high-voltage generator solution enables consistent image quality and long-term system stability. This supports improved process control, reduced defects, and higher customer satisfaction.

Conclusion

X ray high voltage generators are essential components in modern industrial inspection and imaging systems. Their ability to deliver stable, precise, and adjustable power supports a wide range of applications, from non-destructive testing and security screening to food inspection and industrial computed tomography. Selecting the right high-voltage generator solution is critical for achieving reliable performance, accurate results, and long-term operational efficiency in demanding industrial environments.

For organizations seeking dependable X-ray solutions, VJ X Ray develops advanced high voltage generator designs for industrial X ray applications. Their offerings include integrated X ray sources, high voltage generators, and customized power systems for OEM integration. Serving industries such as security inspection, industrial testing, food safety, electronics, and analytical imaging, VJ X Ray focuses on performance reliability, compact system design, and long term support to meet demanding operational and integration requirements.